One of the reasons 3D printing exploded seemingly overnight a decade ago has a lot to do with the RepRap project, an initiative to build a fully open-source and largely 3D-printable 3D-printer. The idea of a machine that could replicate itself was pulled straight from the pages of science fiction, and yet, here were machines–janky, kludgey, barely functional, machines–assembled from parts clearly fabricated by those same machines. They were conceptually impressive, but not a particularly awe-inspiring sight to behold.

And then came Josef Průša and the Prusa Mendel.

Affectionately known as the Ford Model T of the 3D printing world, the Prusa Mendel was the first of the open-source 3D printers that was designed to be easily mass produced. It looked good and it ran great. Released under an open-source license, it was replicated and iterated on a massive scale. That didn’t prevent Průša from building a successful company. The current Prusa i3 MK2 is among the most successful desktop 3D printers in the world, and certainly one of the best.

There are a lot of Prusa i3 clones.

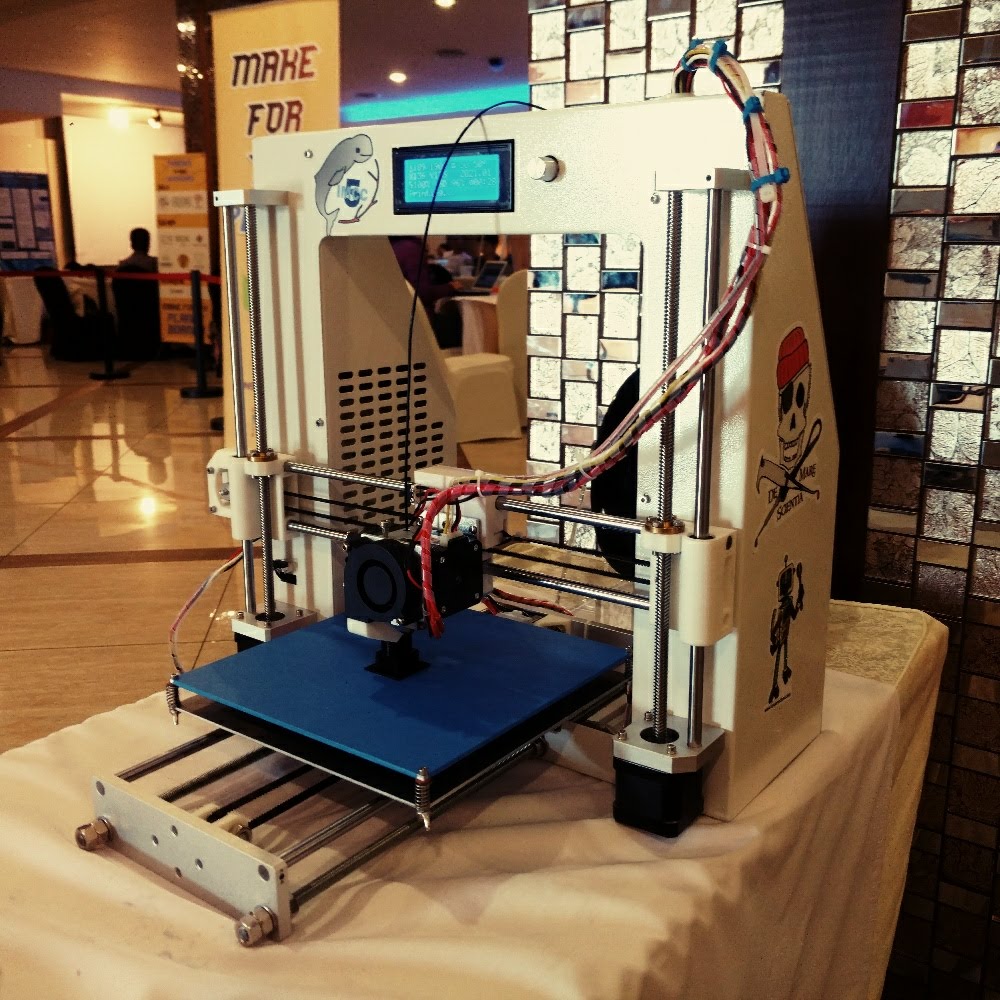

Clocking in at $197.69, the Anet A6 is the most expensive printer in this review series. It’s also the biggest, with a massive 220mm by 220mm by 250mm build area. It’s an upgraded version of the popular Anet A8, with a larger build volume and a better user interface, but not much else. From reviews, this printer seemed like a solid representation of what you can get at the top end of the menagerie of sub-$200 Prusa i3 clones. It (and its smaller A8 brother) certainly have the fan-base and hacking community to support its reputation.

This acrylic-framed beast ships as a kit, so expect to spend half a day putting this printer together.

If you’re going off of dollar per cubic millimeter, this is the best bang for you buck by a wide margin. And that’s about the extent of the good things I have to say about this machine.

For an explanation of our testing protocols, please see: We’re gonna beat the heck out of these machines: The search for the best dirt-cheap 3D printer for fieldwork.

The Burn In.

The Anet A6 is a DIY kit, so the burn in includes building the entire system from laser cut acrylic and standard (though exceptionally low quality) Prusa components. The instructions were fine, with a few weird translation glitches but nothing particularly glaring. If you’ve never seen a Prusa I3 before, it might be a pretty challenging build. They did commit the cardinal sin of laser cut parts: several pieces were semi-symmetric–similar enough that you could assemble them in two configurations, but only one of which would actually work. Generally, when you design DIY laser cut objects, you either make them perfectly symmetrical or obviously asymmetrical so that the user doesn’t spend half a day building something upside down.

Overall, it probably took half-a-day of intermittent work to get this printer built and running.

Almost all 3D printer manufacturers ship their machines with an SD card full of demo prints rendered in g-code. These prints should be ready to go, optimized for that printer, and show off their products best qualities. Anet included a card full of cryptically named prints, so I picked one and awaited my surprise.

Their choice of code to show off the incredible quality and versatility of their printer was this misshapen bust of Shia Lebouf.

Ok then.

I didn’t find this to be particularly well-designed. There were screws in odd places that required clever use of forceps. The electronics are permanently exposed. The contacts for the power supply are not covered. It uses very cheap versions of these flexible shaft couplers that I hate (I find they add to much slop to the z-axis). The SD slot is in an awkward position. And somehow, the bed adjustment thumbscrews managed to be positioned in the single worst place on the entire platform, making adjustment a total pain.

And you will adjust this printer. Every bump, jostle, or sideways glance causes the heated bed to shift.

Burn-in Score: C

The Benchmark Test.

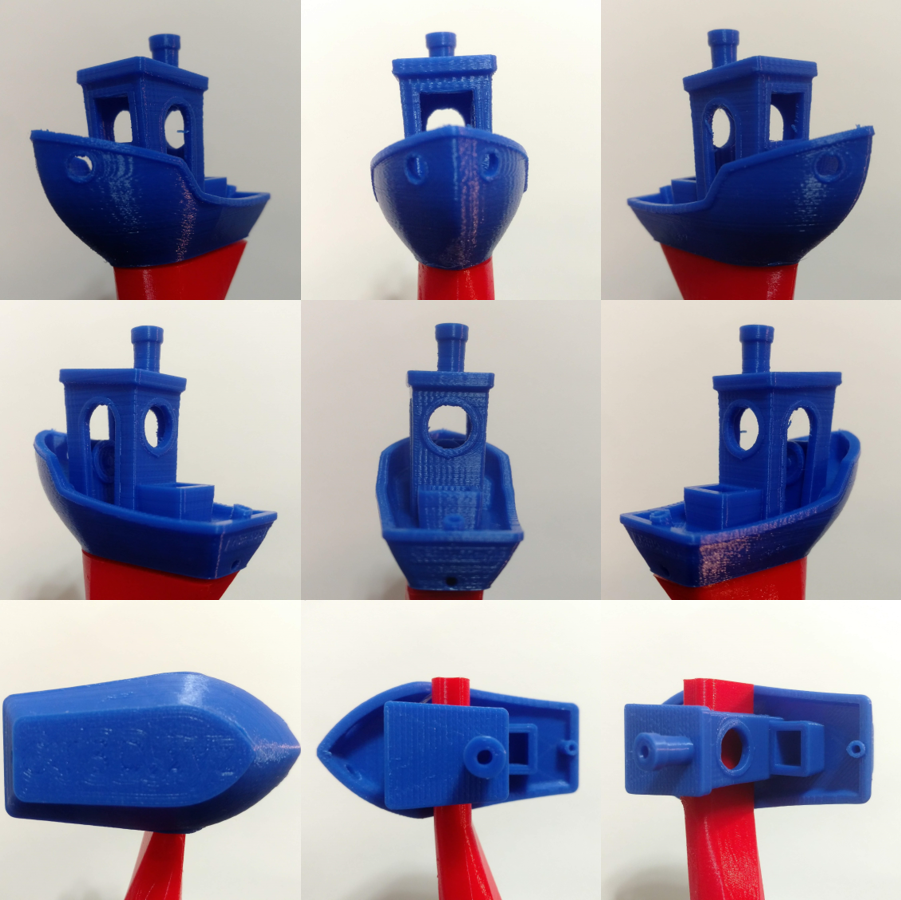

This is a Benchy of subtle error. From a distance, it looks perfectly fine, but on closer examination, you see the tell-tale traces of all possible flaws. Stringing in the doorways. Over-extrusion on the base. Vertical striations (which you’d expect from a cantilever printer, rather than a Prusa-style gantry). Color changes (which tell me that the hot end doesn’t hold a constant temperature). Axis wobble (a little bit on every axis). Surprisingly, it did ok on the bridging. Lots of ghosting, which isn’t a surprise considering the acrylic frame vibrates like crazy.

I spent a lot of time getting this printer dialed in, but this is not a good Benchy.

Benchmark Score: C

The Replication Test.

The Anet A6 fared much better on the replication test. The Octos came out with no major flaws and all look pretty much identical. No complaints.

Replication Score: A

The Functional Parts Test.

On the other hand, the Anet A6 nearly failed this test. The nut and bolt only barely fit together and required rework with a deburring tool before they spun freely. This is caused by poor bed alignment, which should normally be a user error, but here’s the thing: This is a field-use test. I’m not in the field but I try to simulate that kind of use. These printers get moved around, set up in different rooms, placed on a cart and bumped and jostled. This printer loses alignment almost immediately. I’ve spent hours cramming my thumbs into the tight corners of this machine trying to get the bed just right. Sometimes just the motion of the y-axis is enough to break alignment.

Functional Part Score: D

The Complex System Test.

There were no obvious defects on our 3D printable Niskin bottle system, though there was some stringing around the trigger retention loop and the over-extrusion led to tight fits on the pin and servo gear.

The Niskin3D receiver is designed so that the servo fits tightly into the housing and requires no extra adhesive. On all other receivers, this is a nice, tight fit. But the tolerances on this printer aren’t great and the fit for both the receiver and the trigger are sloppy. The Niskin works, but its less stable than other prints.

Complex System Score: B

The Precision Instrument Test.

It’s worse than the Monoprice. But you can still see the tics, so it’s not a complete fail.

Precision score: D

The Educator’s Test.

Hey! This little isopod looks surprisingly good. This design was made to be printed without much fuss and the A6 delivers.

Educator’s Score: A

The Tear-down.

There really isn’t much to tear down, everything is already exposed. I spent a lot of time with this printer leveling the bed and I wish those thumb screws were in a better place. The acrylic on the spool holder already cracked (they cut their logo really close to the edges). There’s no way to tighten the belts short of printing user-created parts and the belt tensioner I made cuts down on some of the print area. The flexible couplers are really soft and cheap. The power supply gets hot enough that I have concerns, has no power button, and there’s no protection around the leads, or the control board, or the LCD.

They did put a lot of thought into wire management, and the routing is clean, simply, and effective. Like the Benchy above, this printer looks really good if you don’t get too close.

This isn’t my first Prusa clone rodeo. During Make for the Planet Borneo, I built a similarly-priced JG Aurora DIY printer whose all metal construction and quality parts really impressed me. Sadly, that printer is out of stock but it left me with high hopes for the $200-tier Prusa clones. No more.

Tear-down Score: C

The Trash Test.

It didn’t actually fail that often, and when it did, it failed right at the beginning

Total mass of waste filament: 6.96g

Reviewer’s Discretion.

You don’t get a printer this big unless you want to print big things cheap, and for that, the Anet A6 really shines! Big Benchy and Giant Giant Isopod look great. It’s also comparably quiet, coming in at 61.2 db.

The flimsy construction and the frail acrylic structure outweigh the benefits. Simply put, this printer will not survive field work. Any jostle sends the user back to re-calibrate, the exposed electronics are a huge hazard, and the power supply sparks whenever I plug it in, which is often because there’s no power switch. It’s clunky, unwieldy, delicate, occupies a huge amount of space, and there’s no way to pack it down for transport. The quality is bad, but there’s a huge support community who’ve come up with dozens of mods to make this thing print even better. It could be a great printer, but you’re probably better off just buying a more expensive machine.

If you have a dedicated space, are willing to do some hacking, and don’t plan on moving it, you could get a lot of good prints out of this machine. But it just isn’t for fieldwork, and for that reason, I’m pulling a full letter grade off its score.

Before I send this printer off to it’s ultimate destination, It seems a shame not to print out an All-American Giant Isopod at glorious, full, 1:1 scale. So that’s what we’re doing.

Final Assessment.

The Anet A6 is not a field printer and for the mods it needs to be a great desktop printer, you could buy a much better machine.

Final Score: D+

The rankings so far

- Creality Ender-3 (with upgrades): A

- Monoprice Select Mini: B+

- Monoprice Mini Delta: B-

- Creality Ender-3 (unmodified): B-

- Anet A6: D+

- iNSTONE Desktop DIY: No

Depending on how successful this project is, I may expand to include printers in the $200 to $400 price range. If you want to help make that happen, you can either use the Amazon Affiliate links in the post to buy printers, consumables, anything else or you can sign up for my Patreon and help support Southern Fried Science.